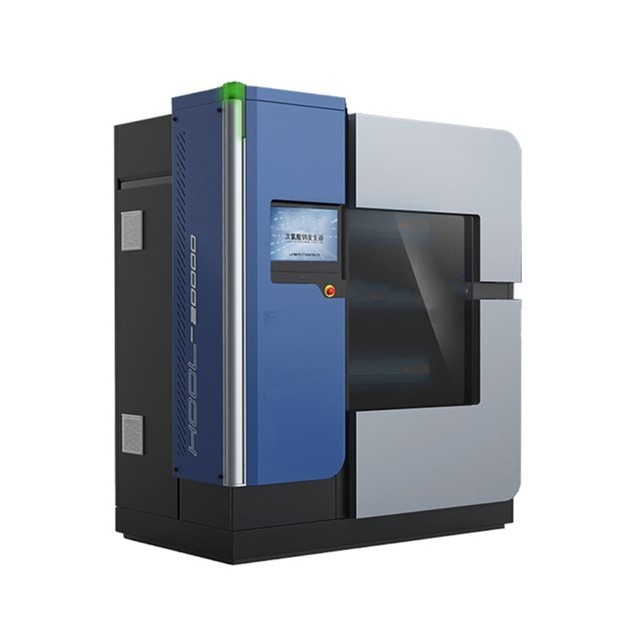

Salt Chlorine Generators (Sodium Hypochlorite Generators)

Salt chlorine generators are devices designed to produce sodium hypochlorite on-site for water disinfection. They typically generate low-concentration sodium hypochlorite by electrolyzing a salt (sodium chloride) and water mixture. These generators are widely used in various applications, such as pool water, drinking water, and industrial water systems, providing reliable and efficient disinfection.

Working Principle:

- Salt Solution Preparation: Sodium chloride (NaCl) is dissolved in water to form a brine solution.

- Electrolysis Process: An electric current passes through this solution, oxidizing chloride ions to produce chlorine gas.

- Sodium Hypochlorite Formation: The chlorine gas combines with sodium hydroxide in solution to create sodium hypochlorite (NaClO), a solution with antiseptic properties, used for disinfection.

Types of Salt Chlorine Generators

- Small-Scale Generators: Commonly used for swimming pools or residential water systems. These devices produce smaller amounts of chlorine.

- Medium-Scale Generators: Suitable for small treatment plants or industrial applications, used to disinfect water and control biological contamination.

- Large-Scale Generators: Provide high-capacity chlorine production for large facilities, such as municipal water treatment plants.

Technological Features

- Automatic Control System: Most generators operate automatically based on the water's chlorine demand, ensuring continuous disinfection.

- Remote Monitoring and Management: Advanced models can be monitored and controlled via internet or mobile applications, facilitating maintenance and monitoring, especially in large facilities.

- Low Energy Consumption: Energy-efficient models reduce operational costs.

- Safety Features: Some generators include safety sensors to monitor gas leaks and overpressure conditions.

Advantages

- No Chemical Storage Required: Reduces safety risks and logistical costs related to the transport of large quantities of chlorine or sodium hypochlorite.

- Easy Integration: Can be integrated into various water treatment and disinfection systems.

- Long-Lasting: Devices manufactured with high-quality electrodes offer durability and low maintenance costs.

Application Areas and Examples

- Municipal Water Treatment Plants: Used to improve drinking water quality and protect public health.

- Industrial Water Systems: Preferred in industrial cooling towers and process water systems to control biological growth.

- Food Industry: Used in chlorinating water to maintain hygiene standards.

- Agriculture and Livestock: Commonly used for disinfecting irrigation water in agricultural areas and drinking water in livestock farms.