Pneumatic Conveying Systems

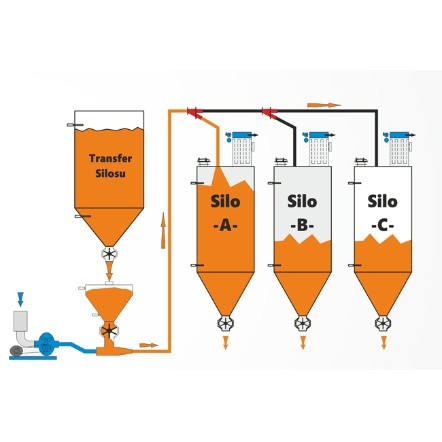

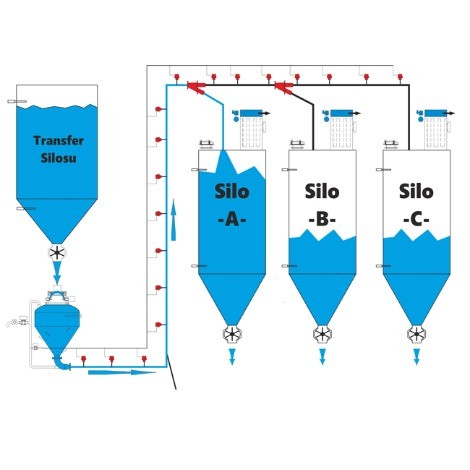

As the name suggests, pneumatic conveying systems consist of equipment used to transfer granules and powdered materials from one point to another via pneumatic methods. The system comprises a compressed air supply unit, a closed pipeline where conveying takes place, and a filter for separating the transported product from the air. During transfer, which occurs in a fully sealed closed line under pressure or vacuum, the material is conveyed without dust formation or product loss. The minimal number of moving parts in pneumatic conveying systems reduces the risk of issues due to friction-based problems.

Pneumatic conveying systems are highly flexible. They allow for feeding from multiple points into a single line, as well as transferring from a single line to multiple points. Dry air can be used for moisture-sensitive materials, while inert nitrogen gas can be employed for explosive materials. Depending on the process requirements, the transfer line can be designed both horizontally and vertically. It is crucial to maintain optimal pressure levels and avoid damaging the structure of delicate materials.

Pneumatic conveying systems can generally be categorized into two groups: dilute phase and dense phase. Systems that require high air volume and low pressure are called dilute phase pneumatic conveying systems, while systems requiring high pressure and low air consumption are known as dense phase pneumatic conveying systems.