Big-Bag Discharging Systems

In industrial processes, the delivery of powdered and granular materials to the end-use point is typically done via silo trucks or big-bags. When there is high consumption, silo trucks are often preferred, whereas big-bags are used for moderate consumption or in cases where silo truck delivery is not feasible. The transfer of powders and granules from big-bags to the required points in the process is only possible through controlled discharge from these bags. Big-bag discharging systems, comprising various components, are designed to facilitate the unloading of materials delivered in big-bags.

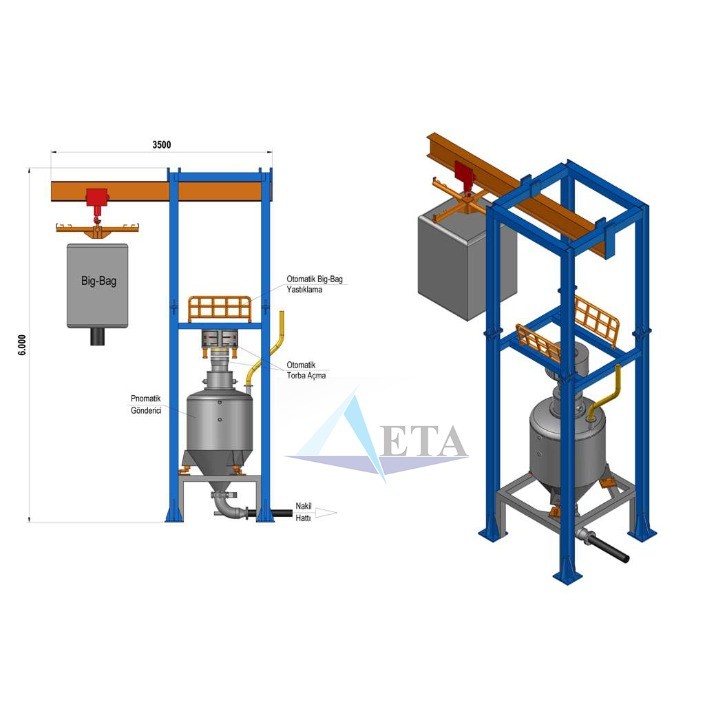

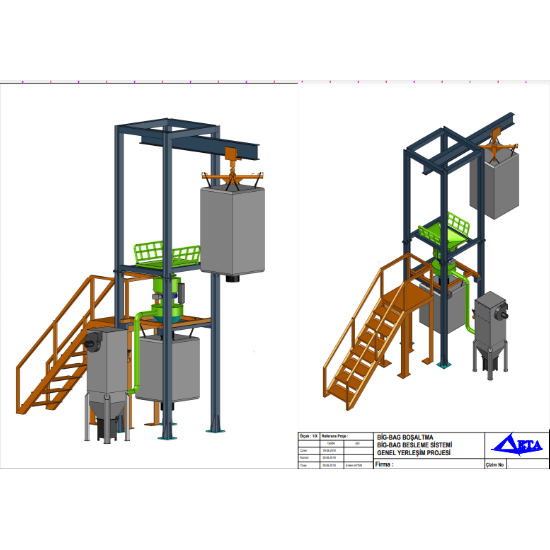

The main component is the carrier frame, built with NPU profiles, which includes an overhead monorail crane. This crane allows the big-bag to be lifted upward and enables easy replacement of an emptied bag with a new one. An extended profile on the frame provides sufficient space for this function. The big-bag is lifted using a custom-designed lifting attachment with four hooks and is placed onto the big-bag seating frame.

Once the bag is positioned on the seating frame, the outlet of the big-bag is clamped into a specially designed airtight area, preventing dust formation and material loss. The seating frame is sloped to facilitate easy discharge of the material from the big-bag. Additionally, pneumatic arms apply pressure to the bag, ensuring a continuous flow of material until the bag is empty. The seating frame is mounted on rubber pads and equipped with special vibration units to aid in the discharge process.