Edi Disc Diffuser

Named after its shape, the disc diffuser is the most widely used diffuser model in wastewater treatment plants. The primary reason for its widespread use is that the disc diffuser has the highest Standard Oxygen Transfer Efficiency (SOTE) value among diffuser models.

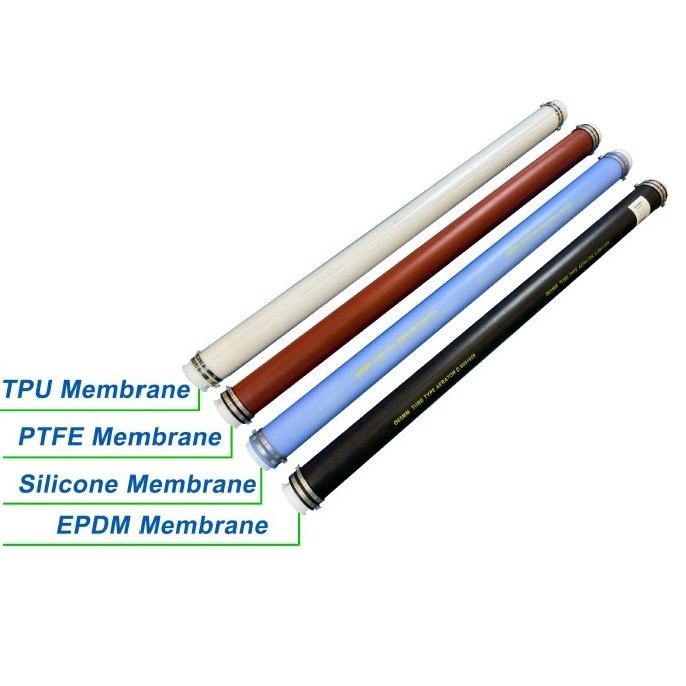

EDI (Environmental Dynamics Inc.) offers both ceramic and membrane disc options. The standard material is EPDM membrane, but other materials such as silicone, Viton, nitrile, HDPE, etc., are available upon request depending on the process requirements. EDI disc diffusers are typically provided with a ¾ inch threaded connection as standard. However, slide-type models are also available upon request.

EDI uses high-quality EPDM material in the production of its membrane disc diffusers. The EPDM membrane stands out from competitors in terms of flexibility, tensile strength, elongation capacity, tear resistance, hardness, and oil content, ensuring maximum membrane lifespan. EDI disc diffusers, with their patented perforation technology, offer maximum oxygen transfer efficiency and feature a fiberglass-reinforced polypropylene body material that is protected against UV rays.

The internal check valve technology ensures minimal pressure loss and prevents wastewater from leaking into the pressurized air line in case of membrane tears. EDI disc diffusers are available in 7, 9, and 12-inch sizes. In addition to models with standard airflow capacity, high-capacity models are also kept in stock.