Aquaturbo High Speed Floating Surface Aerator

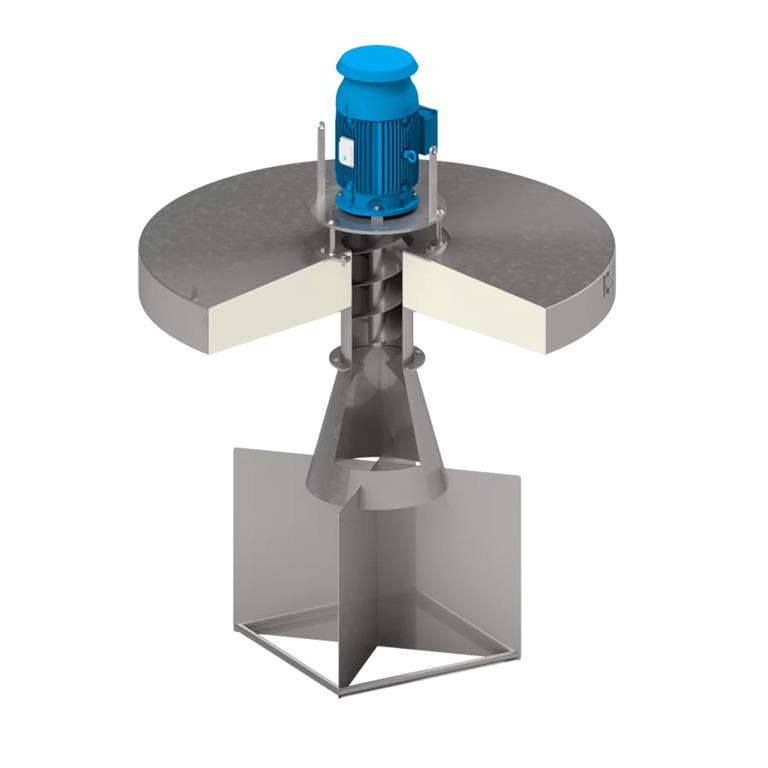

The turbo surface aerator operates like an open impeller pump. The impeller (screwpeller), driven by the electric motor, creates a vacuum that draws in wastewater through the suction cone and then discharges it into a cylindrical housing with the help of the screwpeller. The wastewater is then horizontally sprayed out from the plate at the cylindrical housing’s outlet. As the wastewater remains suspended in the air until it falls back into the basin, it comes into contact with oxygen. The surface aerator continuously recirculates the wastewater, consistently increasing the oxygen content within it.

The turbo aerator is directly coupled to the electric motor, eliminating the need for an additional gear reducer. This feature provides the advantage of transferring the power from the electric motor directly to the wastewater via the screwpeller without any loss, resulting in lower energy consumption and significant operational cost savings. Aqua turbo aerators, featuring patented screwpeller technology, have an oxygenation efficiency of 1.5 kg O2/kWh. This performance, almost equivalent to the efficiency of blower and diffuser systems, makes turbo aerators an attractive option for wastewater aeration basins.

With a 5-year maintenance-free guarantee and a design that ensures easy maintenance, Aqua turbo aerators offer users a solution to the frequent and challenging maintenance issues commonly associated with alternative technologies in wastewater aeration processes. In addition to oxygenation, turbo aerators provide effective mixing, preventing the formation of anaerobic conditions due to potential sludge settling during non-continuous aeration periods in winter.