SA Engineering Air Foil Bearing Turbo Blowers

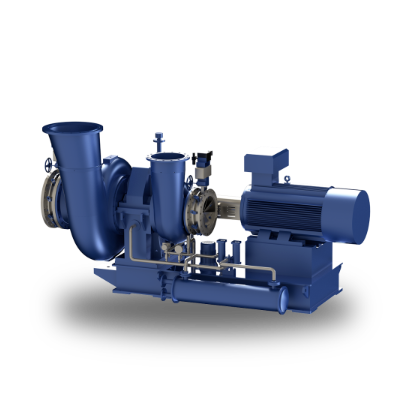

The SA Engineering turbo blower utilizes a specially alloyed aluminum fan to produce compressed air. The aluminum fan is directly coupled with the rotor. The blower features one axial and two radial bearings, which provide frictionless support for the rotor. Once the turbo blower reaches a certain speed, the air drawn in from the environment creates a hydrodynamic pressure effect between the bearings and the rotor, forming an air cushion. This technology, known as air bearing turbo blower, generates 100% oil-free compressed air.

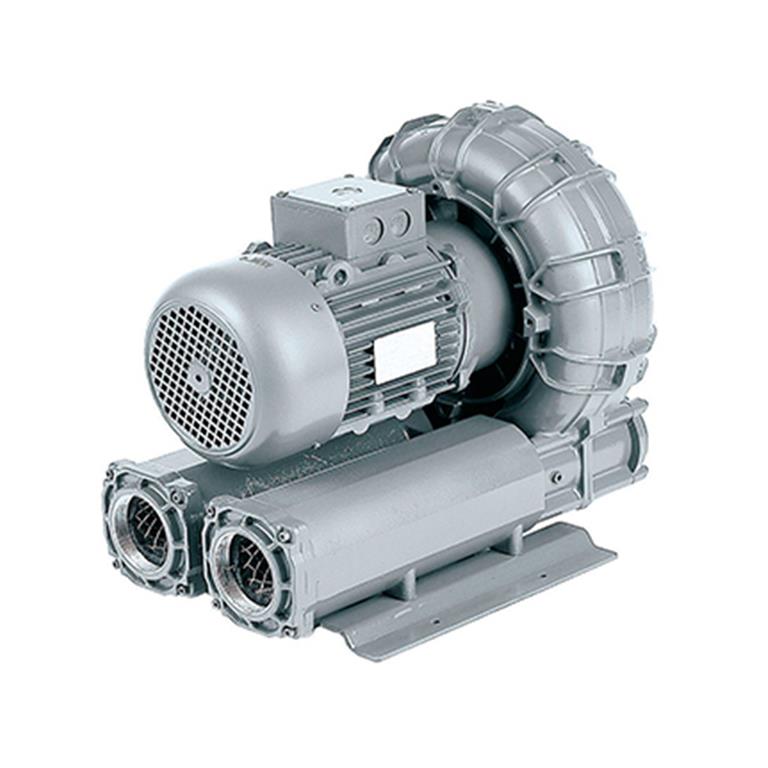

In Roots blower technology, roller bearings are used to minimize friction, and mineral or synthetic oils are employed to reduce friction and provide cooling. In contrast, the SA air bearing turbo blower technology requires no lubrication since the bearing support is provided by the air drawn from the environment. Another distinguishing feature of air bearing turbo blower technology is its high energy efficiency. Since the air bearing technology minimizes friction losses, a significant portion of the energy drawn from the power grid is transferred to the centrifugal fan. In other blower technologies, the power drawn from the grid is significantly lost in power transmission elements like belts, pulleys, and gearboxes, or in the bearing systems required by the technology. As a result, energy efficiency is maximized in air bearing turbo blower technology.

Additionally, by using the frequency inverter included in the air bearing turbo blower, the airflow rate can be adjusted between 45% and 100%. This allows the provision of only the necessary amount of compressed air for the process, preventing unnecessary power consumption. During capacity changes, the system's efficiency loss is minimal compared to other technologies.

Due to its manufacturing technology, the SA Engineering turbo blower operates with low noise and vibration levels. It works within the noise range of 70-80 dB, compliant with occupational health and safety standards, without the need for additional sound insulation systems.